3D CAD software for

electrical cabinets and shelters

Computer-Aided Design for

3D Electrical Cabinet Design

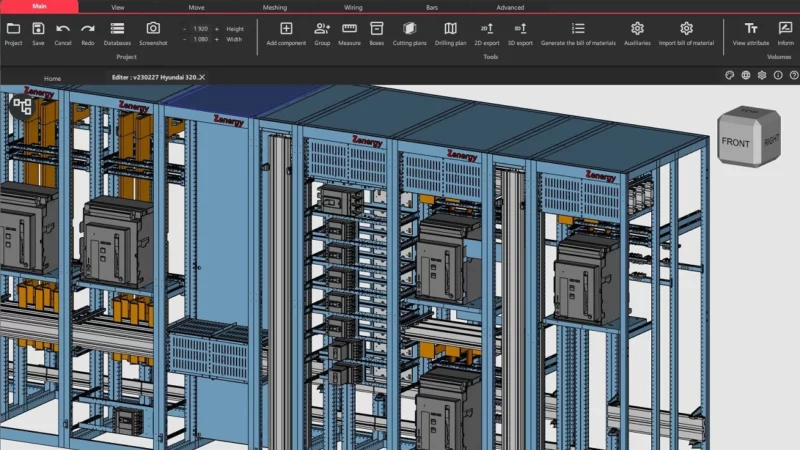

FTZ-Panel 3D is an innovative software for 3D modelling of electrical cabinets and panels, offering a realistic environment.

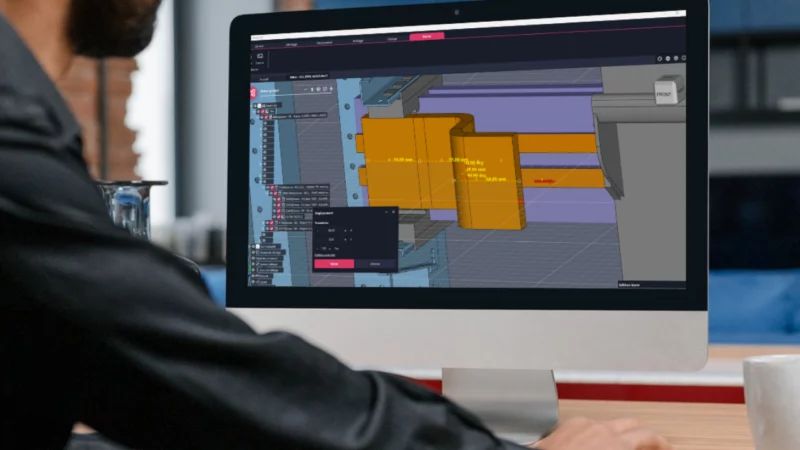

FTZ-Panel 3D is a powerful software that facilitates the integration of busbars into the design of your three-dimensional electrical panels…

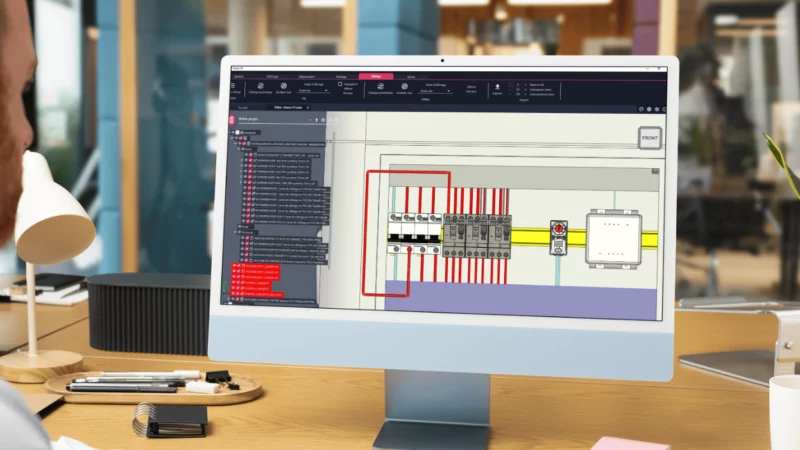

FTZ-Panel 3D offers advanced ‘wire routing’ functionality to optimise cabling. Based on the schematic data…

FTZ-Panel 3D is also used for assembling modular cabinets: panels, rails, front panels, etc.

FTZ-Panel 3D completes any parts lists in the diagram with the added hardware and quantities: box, rail, duct, bar, etc.

Additional features

FTZ-Panel 3D also includes a macro language that enables the creation of customised configurators.

FTZ-Panel 3D ensures precise wire routing. Thanks to an advanced algorithm…

Thanks to its simplified and ergonomic design, the FTZ-Panel 3D is particularly quick to learn.

What our customers say

The answers to your questions

Volumes are usually available directly from manufacturers’ websites. They can also be easily modelled using 3D mechanical CAD software.

FTZ-Panel 3D is completely self-contained. It also has built-in functions to simplify 3D volumes if required.

Yes, it’s perfectly possible to create an enclosure layout without a diagram by importing a bill of materials or loading the components.

Most of the time, the list comes from the SchemELECT schematic CAD software, defined on the basis of the electrical diagram. You can also import a list of equipment if you don’t want to create the schematic.

Yes, snap handles can be used to create a magnetic effect in the 3D view for simplified positioning. Additives are also managed to facilitate their placement in relation to the main component.

Yes, there is a function to control collisions, guaranteeing quality assembly.

Yes, FTZ-Panel 3D can be used to manage several cabinets as well as external equipment. It manages the entire installation, including cabinets, motors, consoles, etc.

Yes, the user can define the drilling plans. These plans can be used in the workshop via CNC machines.

Yes, dedicated functions can be used to define copper bars in 3D. Using the bending database, FTZ-Panel 3D automatically generates the corresponding bending plans.

Yes, the software allows you to calculate the actual lengths of wires and cables precisely, which makes it easier to prepare the wiring, optimises assembly time and ensures that the same wiring is used in the same cabinets.

Yes, the user defines the paths at the time of installation. The software then automatically generates the wire paths, which can be adjusted if required.

Yes, FTZ-Panel 3D generates a list of wires and cables with their actual lengths, compatible with automated cutting machines.

No, FTZ-Panel 3D is not just for panel builders. It is also used by companies wishing to obtain a realistic view of their enclosures in 3D, such as engineers, design offices and installers.

Yes, once the layout has been completed in FTZ-Panel 3D, the FTZ-Wiring Assistant software takes over and supports the assembly of components and wiring in the workshop.

contact us