Optimising the design of electrical cabinets: 4 concrete levers provided by CAD

As a member of an electrical design office or panel builder, you know better than anyone: designing an electrical cabinet is not just a matter of wiring. It’s a real piece of design work that requires time, skills and rigour.

Today, it’s possible to automate a large part of this process, while gaining in reliability, time and clarity. Thanks to CAD dedicated to electrical cabinets, more and more design offices and panel builders are succeeding in doing just that.

At FTZ, we’re supporting this transition with practical tools. In this article, we show you how to optimise your working method, step by step, thanks to the synergy of SchemELECT and FTZ-Panel 3D software.

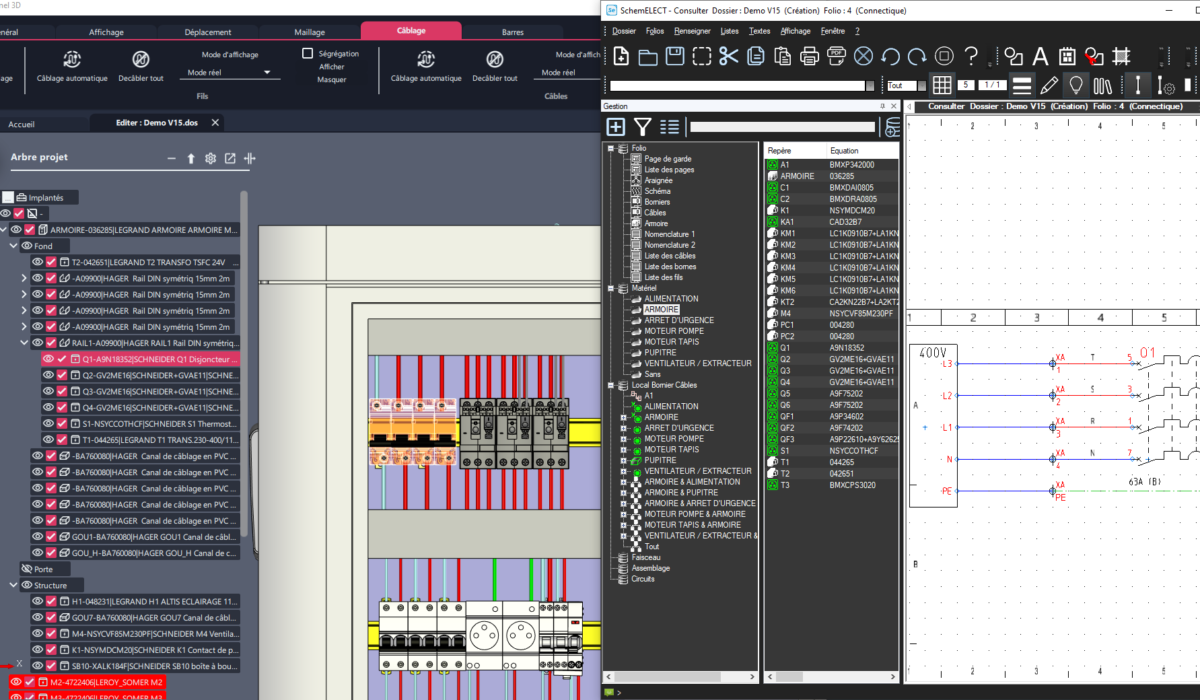

Lever #1: Automatically integrate your components from the diagram

It all starts with the electrical schematic. Thanks to SchemELECT, the diagram can be used to associate electrical symbols with components. This list of components can be reused directly in FTZ-Panel 3D in the form of a volume tree.

Clearly ? No more Excel spreadsheets, no more copy and paste and no more updating errors. This avoids re-entering errors, saves time and, above all, ensures consistency between the schematic study and the physical design of the enclosure.

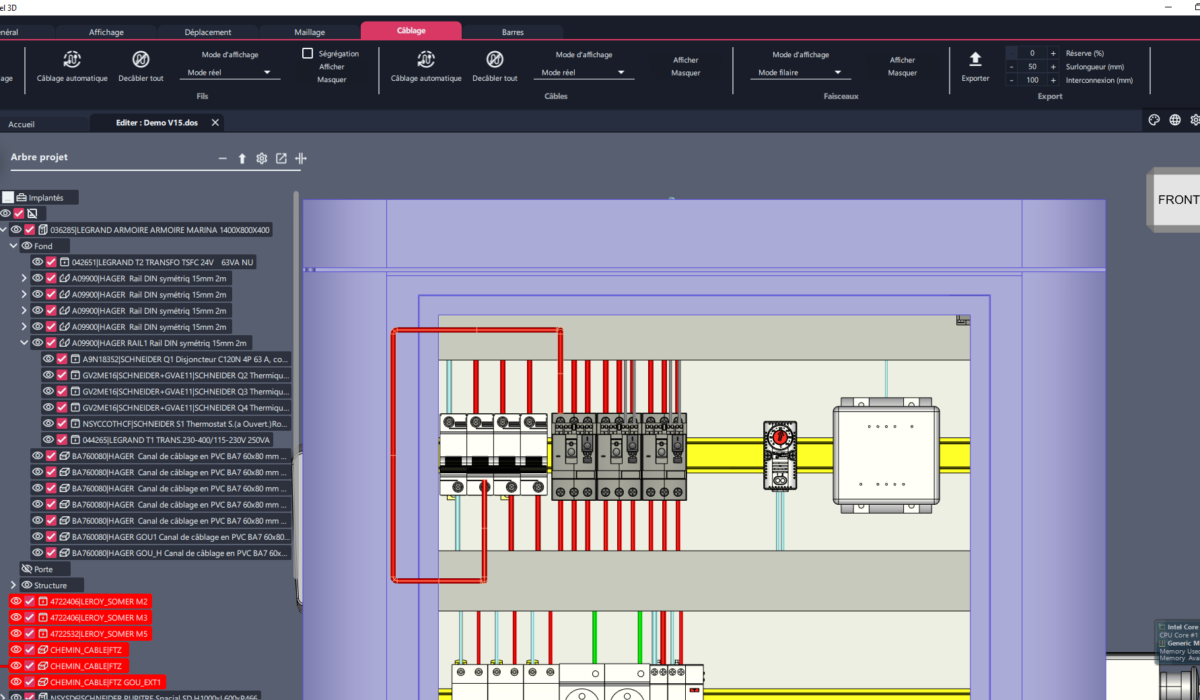

Lever #2: Implement components quickly

Once the components have been loaded as volumes, FTZ-Panel 3D takes over. It offers you rapid installation in the cabinet using simple drag-and-drop operations, facilitated by magnetic hooks, or even automatic installation according to your internal rules. FTZ-Panel 3D complements this layout with busbar management.

The result: fast, consistent and reliable positioning. And above all, you can move forward much more quickly.

Lever #3: Delegate wire routing (without losing precision)

Wiring is often a real headache. Fortunately, FTZ-Panel 3D is capable of automatically calculating wire routing, based on the layout and an optimised algorithm.

The lengths are accurate, the paths are defined, and everything is designed to facilitate work in the workshop by interfacing with a numerically-controlled machine, for example. Less to-ing and fro-ing, fewer errors, and greater peace of mind.

Lever #4: Produce a production-ready digital twin

The end result is an accurate and complete 3D model of your cabinet. This digital twin can then be used by the various departments: project manager, manufacturing or maintenance. Everyone works with the same data, with no approximations.

That’s what we call a real gain in terms of data fluidity and collaboration between departments.

What's in it for you ?

Adopting CAD software for electrical cabinets means :

- Reducing the time spent on each study

- Avoiding copying errors

- Improving standardisation from one project to another

- And above all, freeing up time for complex or innovative projects

In short, it’s a method that gives you greater control, quality and profitability.

Conclusion

Automating the design of an electrical cabinet doesn’t mean delegating everything to software. It means working more rationally, concentrating your efforts where they really count.

With FTZ-Panel 3D and SchemELECT, you have solid tools at your disposal, designed to save you time, make your projects more reliable and improve your responsiveness.

Why not take your electrical design to the next level ?