The importance of P&ID diagrams in piping design

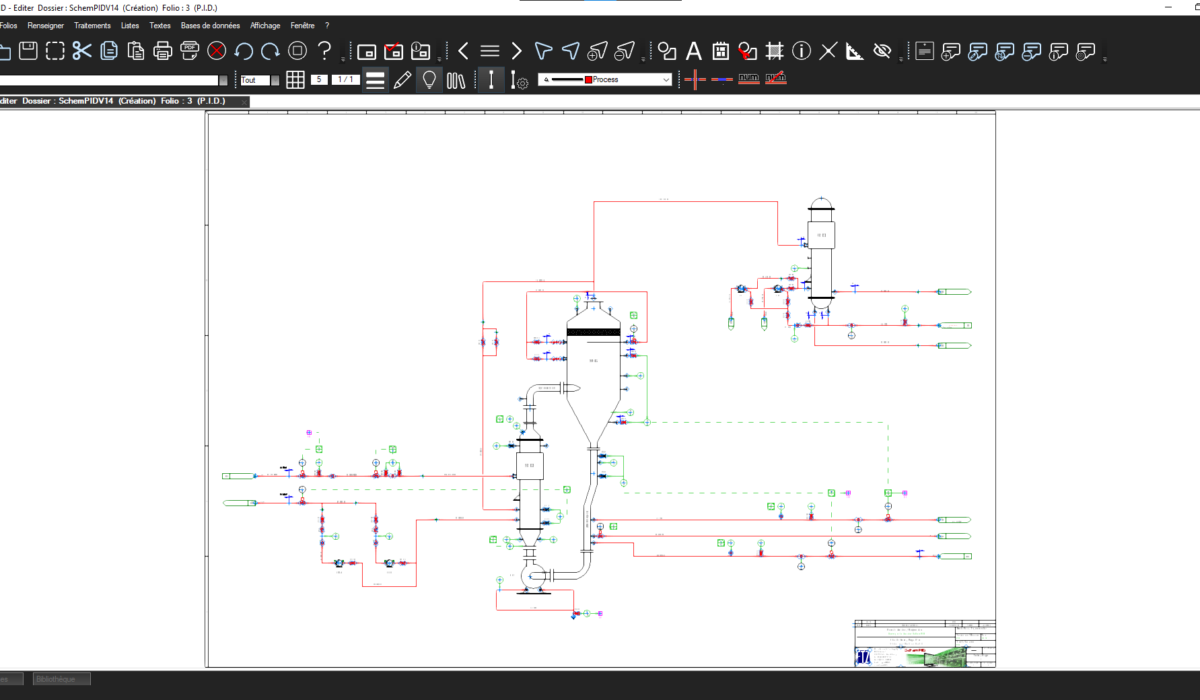

In industry, the design and construction of new installations depends on reliable and accurate technical documentation. The Piping and Instrumentation Diagram (P&ID) is one of the essential tools used by design offices and new works departments on a day-to-day basis. Coupled with the power of CAD (Computer Aided Design), it becomes a real asset for optimising the design, construction and commissioning of industrial projects, particularly with solutions such as SchemPID.

P&ID diagram: a valuable map for industrial projects

A P&ID diagram is more than just a technical drawing. It accurately describes the piping, equipment, sensors and control instruments of an industrial installation. This reference document, produced using advanced CAD tools, is essential for the design, planning and validation of industrial installations.

Why is the P&ID essential for design offices?

- A solid basis for design

Right from the design phase, the P&ID diagram enables the architecture of the systems and their interconnections to be precisely defined. It facilitates technical choices and guarantees the coherence of future installations.

- Better coordination between the various trades

A well-developed P&ID ensures smooth communication between the design, works and commissioning teams. It reduces the risk of errors and optimises completion times.

- Precise, secure planning

The P&ID is an essential tool for preparing the work: identifying the equipment to be installed, the circuits to be tested and the commissioning sequences. It enhances the safety of operations and the quality of installations.

SchemPID: the ideal CAD tool for your industrial projects

To create and use your P&ID diagrams efficiently, FTZ offers SchemPID, an industrial CAD solution tailored to the needs of design offices and new build projects. Designed for professionals, SchemPID offers :

- Standardised symbol libraries for fast, universal reading.

- Simplified schematics with advanced connectivity and information distribution along the lines.

- Simplified instrument management

- Easier choice of equipment thanks to advanced filter functions linked to the database and predefined classes

- Consistency of data with online and post checks

- Centralised management of equipment data: access data sheets, design data and specifications in just a few clicks.

- Simplified updates to ensure documentation is always in line with project developments.

- Provision of customisable lists and bills of materials for the various departments.

- Seamless integration with your ERP, PLM and other industrial CAD platforms, for comprehensive project management.

Conclusion

With SchemPID, your design and new works teams gain in precision, productivity and deadline control.

Maintenance and commissioning teams have all the data they need to operate the installation.

To optimise the management of your industrial projects and strengthen your design strategy, put your trust in FTZ’s expertise and adopt SchemPID for your P&ID diagrams !