Why change CAD software for your industrial electrical diagrams?

In today’s industrial context, the requirements for electrical design have become much tougher: lead times are getting shorter, regulatory standards are becoming more complex, component traceability is essential, and collaboration between departments (electrical, automation, maintenance) must be fluid and structured. In this context, using CAD software for industrial electrical diagrams that has not been updated for several years means slowing down the design process and increasing the risk of errors.

Yet many design offices are still using obsolete or non-specialised tools, often out of habit or for the sake of continuity. These tools are used on a day-to-day basis for industrial electrical diagrams, despite the fact that they are general-purpose drawing software (CAD), with no business logic, or an old version that has been frozen for a long time.

Increasingly stringent requirements for electrical design

In an environment where every error can lead to delays or even penalties, this choice can seriously hamper the overall performance of the electrical design office or automation department.

In addition, unsuitable CAD software for industrial electrical diagrams often involves tedious manual input, with no assistance in checking connections or intelligently locating wires or components. Terminal block management becomes a source of errors or is not carried out at all, parts lists have to be produced by hand, and the final documentation guarantees neither compliance with standards nor optimum legibility for assembly or maintenance teams. These technical limitations are not immediately apparent, but they accumulate with each project.

Changing software may seem complicated, but changing nothing is often even more so. In the long run, continuing to produce industrial electrical diagrams with outdated or overly general CAD software exposes teams to a considerable waste of time, repetitive design errors, incomplete files and increasing difficulty in maintaining a clear and reliable technical repository. This affects the entire productivity of the project team, from the design office right through to the workshop.

SchemELECT: an alternative designed for industrial electricity

High-performance CAD software for industrial electrical diagrams does more than just draw: it structures information, automates repetitive tasks, secures technical data and guarantees document conformity. SchemELECT has been designed by specialists in the field to meet these challenges.

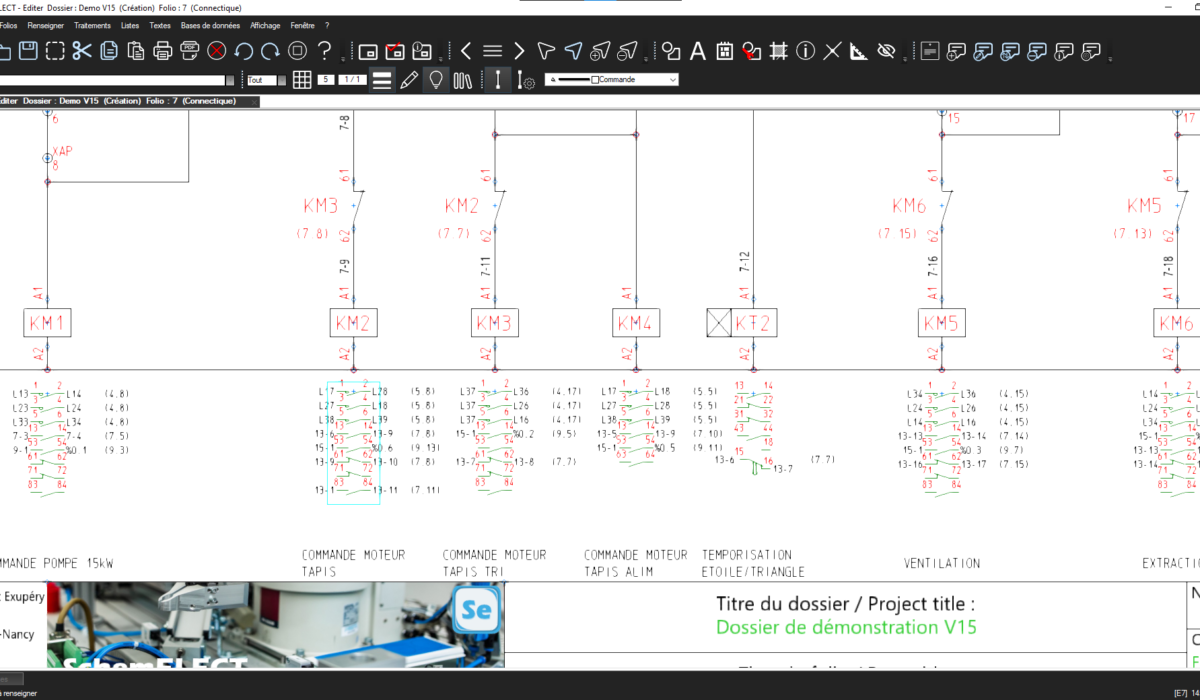

SchemELECT incorporates functions that are essential for industrial electrical projects, such as automatic generation of terminal blocks, wire identification, dynamic creation of bills of materials, automatic connection control, 2D or 3D cabinet layout and export of drawings in standardised formats. All these functions can be accessed directly from an interface designed for tradespeople in the field: electricians, automation engineers, integrators, new build and maintenance technicians.

Improving efficiency and reliability at every stage of the project

With SchemELECT, users considerably reduce the time spent on studies, limit the risk of errors and provide very complete files. They also have access to a coherent, structured work base that can be used during both the design and maintenance phases. Last-minute changes, which are common in industrial projects, can be incorporated while maintaining the overall coherence and integrity of the project.

Changing CAD software for industrial electrical diagrams isn’t just about modernising a tool: it’s about improving productivity, enhancing quality and laying the foundations for a more robust technical organisation. SchemELECT is a proven solution for taking this step safely, while increasing the efficiency and reliability of your electrical projects.