In the industrial world, an industrial electrical diagram is not just a design document: it is a transcription of the operation, safety and reliability of an installation.

To be usable and sustainable, it must be produced in accordance with best practice and address the various departments that use this data.

But in concrete terms, what does this expression mean, and how does SchemELECT help designers to comply with it on a daily basis?

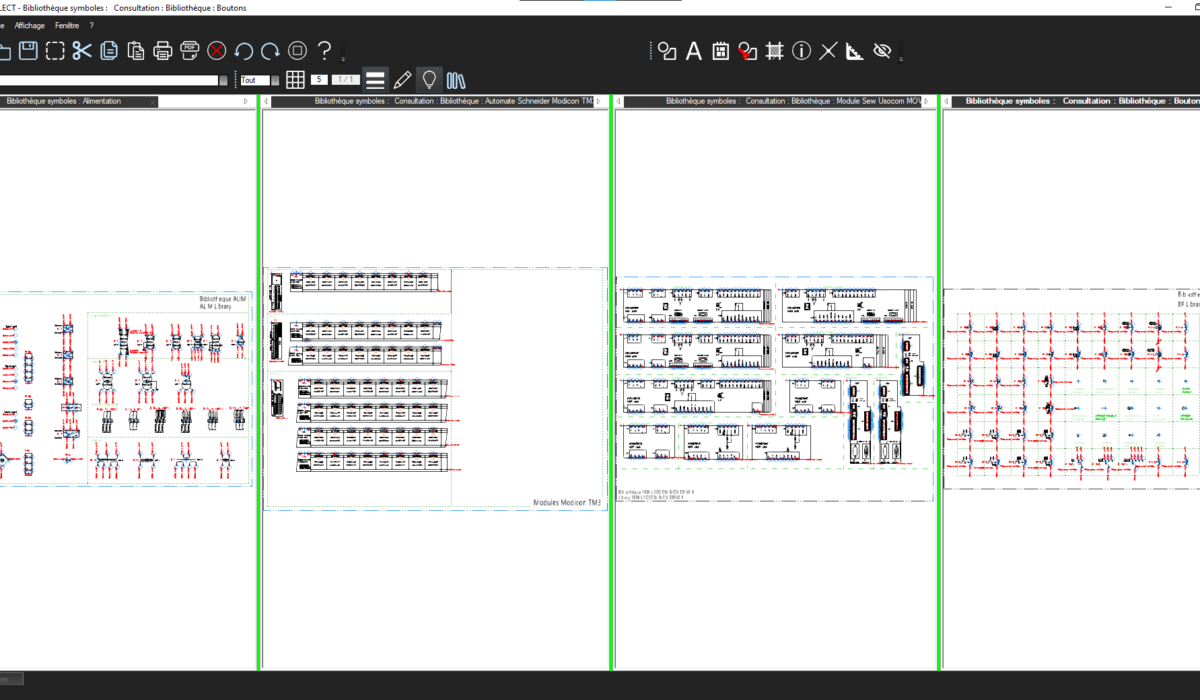

Controlled normative and symbolic compliance for a reliable industrial electrical diagram

Standards form the basis of any well-designed industrial electrical diagram. It must comply with the standards in force in the country concerned.

With SchemELECT, these requirements are integrated from the design stage onwards.

The software offers a library of standardised symbols and naming rules that comply with the standards of the country of use, thus ensuring the compliance and consistency of the industrial electrical diagram project.

The decisive advantages of SchemELECT and FTZ-Panel 3D at IP France

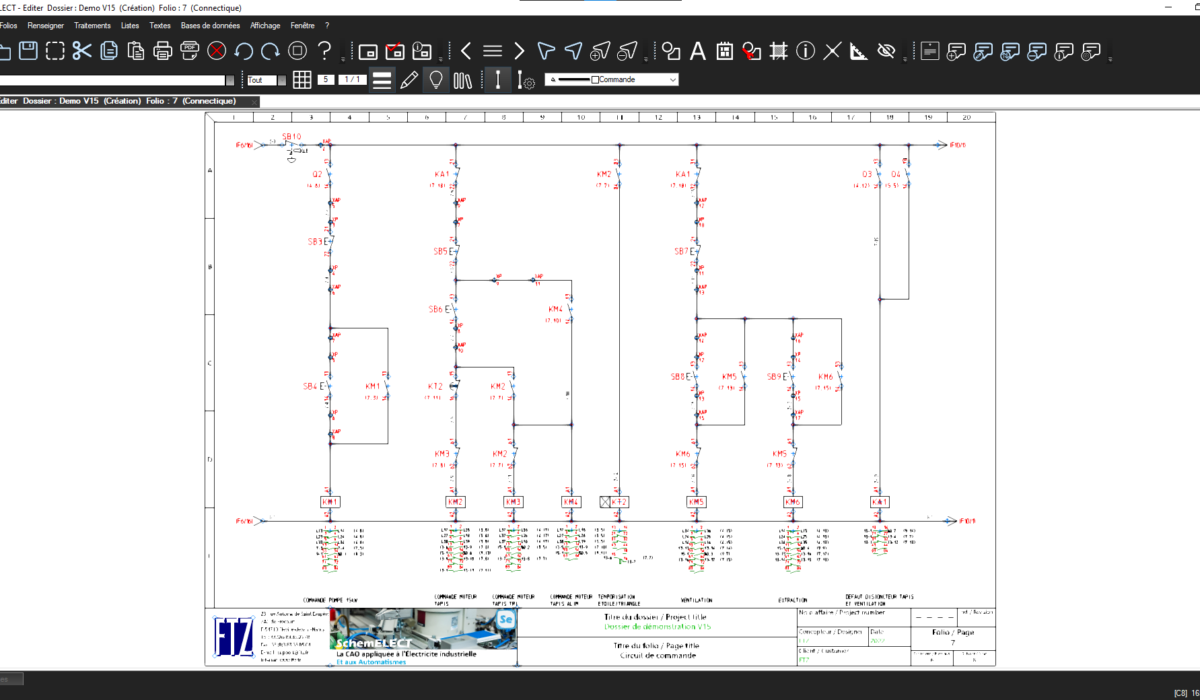

A professional industrial electrical diagram must be structured logically, with a clear organisation covering the different parts of the diagram: the synoptic, power, control and automation.

SchemELECT facilitates this process thanks to:

- the functional structuring of the project, the basis of which is defined in the software,

- automatic and consistent symbol identification,

- dynamic cross-referencing of page references,

- automatic wire numbering.

These functions ensure perfect consistency between all elements of the file, even for complex or large projects.

Consistency between the industrial electrical diagram and the physical layout

One of the key points of best practice is ensuring consistency between industrial electrical diagrams and physical reality: cables, terminal blocks, cabinets, etc.

SchemELECT ensures this consistency by automating:

- the link between the diagram and the cabinet layout plan,

- the management of terminal blocks and cables,

- the cross-checking of connections (parent/child symbols).

As a result, the design file becomes a true reflection of the actual installation, significantly reducing wiring errors and commissioning times.

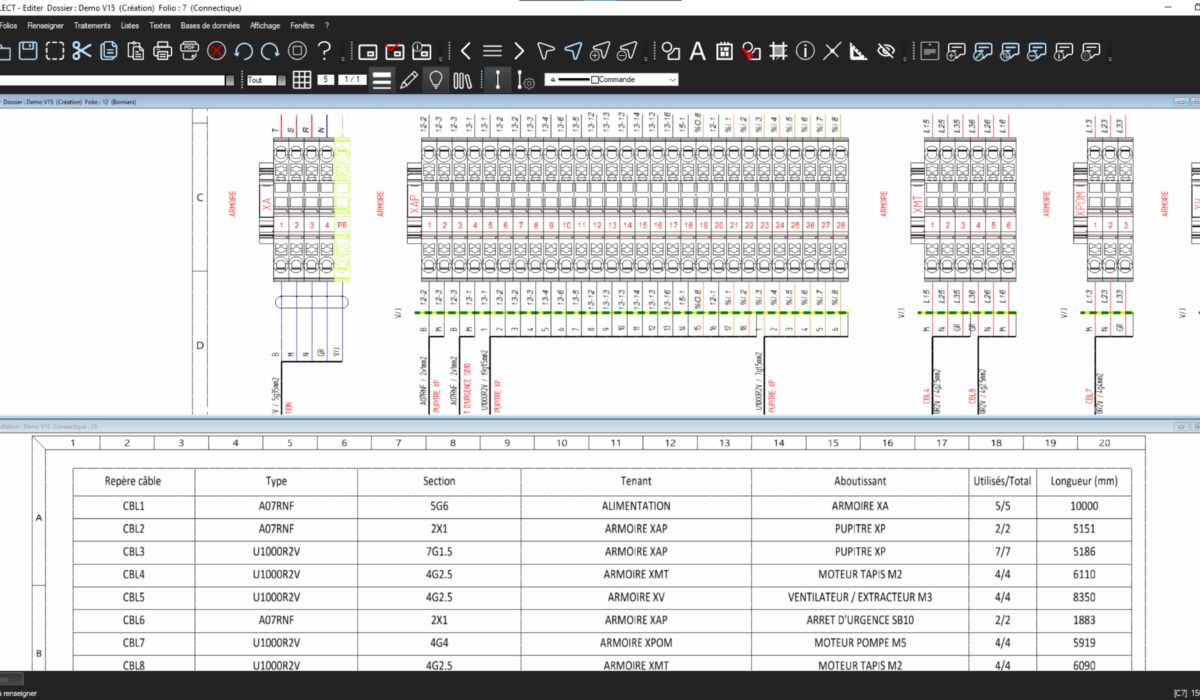

Complete documentation and full traceability of industrial electrical diagrams

Best practice requires that a complete and usable file be provided at each stage of the project.

SchemELECT automatically generates:

- the folio summary,

- the equipment lists and parts lists,

- the cable log,

- the various labels,

- the change indices.

All of these documents are linked to the industrial electrical diagram, ensuring full traceability and automatic updating in the event of changes.

IClarity, legibility and graphic efficiency of industrial electrical diagrams

The readability of an industrial electrical diagram determines its quality and ease of use.

Thanks to its user-friendly design and advanced graphic tools, SchemELECT makes it easy to create diagrams with a neat layout:

- clear, hierarchical and easy-to-read diagrams,

- automatic alignment and positioning of elements,

- a consistent and standardised layout,

- an overall aesthetic

This allows designers to focus on the technical content without wasting time on formatting.

Conclusion

Creating an industrial electrical diagram in accordance with best practices requires a combination of regulatory rigour, technical consistency and clarity.

With SchemELECT, these requirements become easy to apply on a daily basis:

the software integrates standards, automates checks and structures projects according to best practices in electrical design.

In short, SchemELECT transforms the technical discipline of best practices into a smooth, controlled and productive process.